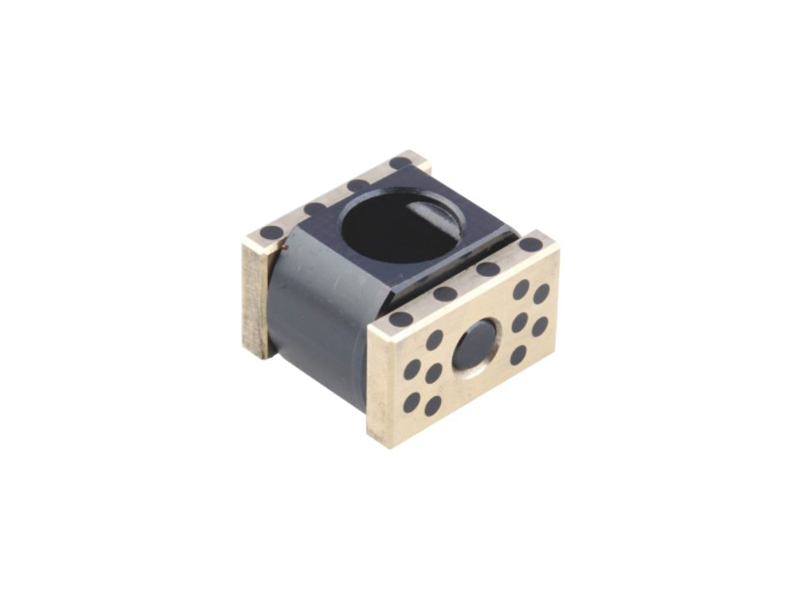

In the realm of injection molding, where precision and accuracy are paramount, Multi Glide Slide Core Pulling stands out as a versatile and crucial approach. It involves the use of multiple slides and cores, each meticulously designed to work in harmony, facilitating the removal of complex molded parts from the mold.

The main objective of Multi Glide Slide Core Pulling is to enable the production of intricate parts that would be difficult, if not impossible, to create using conventional molding techniques. It enhances design flexibility, reduces material waste, and minimizes the need for secondary operations or trimming, all while maintaining strict tolerances and high part quality.

Key Features and Advantages of Multi Glide Slide Core Pulling:

Complex Part Extraction: This technique enables the extraction of parts with undercuts, threads, and interlocking features that would be challenging to remove using traditional molding methods.

Enhanced Design Flexibility: Manufacturers have greater freedom to design complex parts without being constrained by mold release limitations. This results in innovative and more intricate component designs.

Reduced Material Waste: Multi Glide Slide Core Pulling minimizes material waste by allowing for the production of intricate parts without the need for extensive secondary processes like trimming or machining.

Precision and Accuracy: The technique ensures that extracted parts maintain their precision and quality, meeting stringent industry standards and customer requirements.

Automation Integration: Multi Glide Slide Core Pulling can be seamlessly integrated into automated systems, enhancing manufacturing efficiency and reducing labor costs.

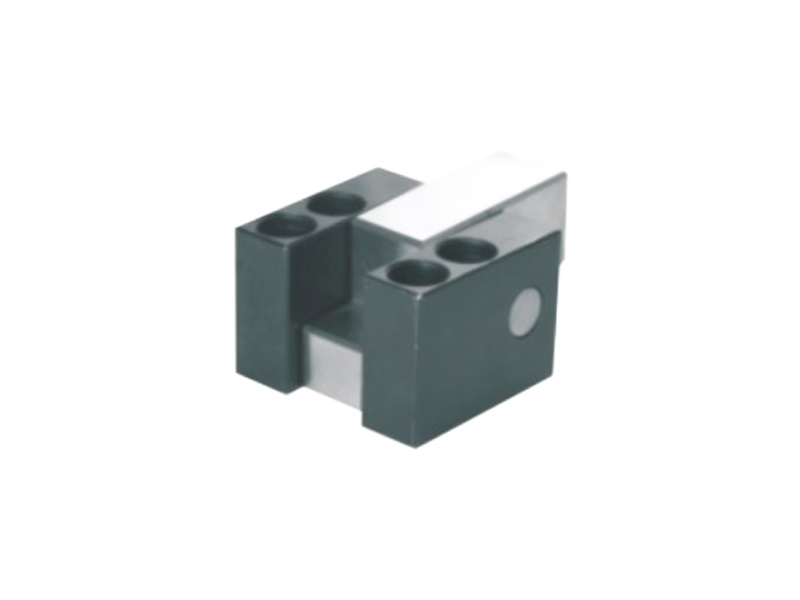

Universal Oblique Guide Rod Seat

The Universal Oblique Guide Rod Seat is a critical component used in various industrial applications, particularly in machinery and equipment where linear motion and precision are essential. This component plays a pivotal role in guiding and supporting oblique guide rods, ensuring smooth and accurate motion.

The Universal Oblique Guide Rod Seat is designed to accommodate oblique guide rods at specific angles, allowing for controlled movement in multiple directions. This versatility makes it a valuable addition to machinery where components need to move in non-linear or oblique paths.

Key features of the Universal Oblique Guide Rod Seat include its durable construction, precise alignment, and the ability to handle substantial loads. The use of high-quality materials and precision engineering ensures its longevity and reliability in demanding industrial settings.

Industries such as automation, manufacturing, and robotics rely on the Universal Oblique Guide Rod Seat to facilitate complex movements and ensure the accuracy of machinery and equipment. Its adaptability and robustness contribute to improved productivity and the overall efficiency of various industrial processes.

Multi Glide Slide Core Pulling

Multi Glide Slide Core Pulling is a technique employed in injection molding to extract complex, internally undercut features from molds. It is an essential process for producing intricate components and is particularly useful for parts with challenging geometries.

This method involves using multiple slides and cores to pull and release complex molded parts. The slides and cores are intricately designed and operated in a coordinated manner to facilitate the removal of undercuts, threads, or interlocking features from the mold.

Multi Glide Slide Core Pulling offers several advantages. It enables the creation of parts with complex geometries and undercuts that would be challenging or impossible to produce with conventional molding techniques. This method enhances design flexibility, reduces material waste, and minimizes the need for secondary operations or trimming.

In industries such as automotive and consumer electronics, Multi Glide Slide Core Pulling is instrumental in producing components with precision and accuracy. The ability to extract complex parts without defects or damage is critical in these sectors, where high quality and consistency are paramount.

The technique involves a sophisticated control system that coordinates the movement of slides and cores. Additionally, the choice of materials for the slides and cores is crucial to ensure durability and precision.

Multi Glide Slide Core Pulling is a versatile and essential technique in the injection molding industry. It empowers manufacturers to create complex components with high precision, reduces waste, and enhances design possibilities. This method plays a significant role in various industries, contributing to the production of high-quality, intricate molded parts.